Encoder Failure | Repair Service Company

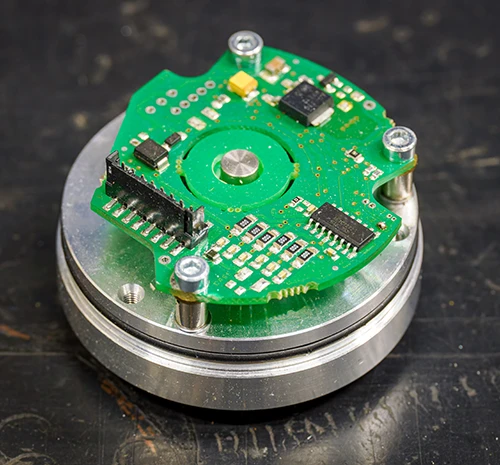

Servo Spindle Specialist performs repairs and service on encoders. Encoders are precise electronic devices sensitive to contamination. Many also have bearings that can wear out over time. Installing them requires specialized equipment for accurate alignment with motor poles.

If your encoder is malfunctioning, it can cause errors in positioning and potentially damage other components of the servo motor. This can lead to costly downtime and reduced productivity. That’s why it’s important to have your encoders regularly inspected and maintained by trained professionals.

If your encoder is malfunctioning, it can cause errors in positioning and potentially damage other components of the servo motor. This can lead to costly downtime and reduced productivity. That’s why it’s important to have your encoders regularly inspected and maintained by trained professionals.

Our team at Servo Spindle Specialist has years of experience working with various types of encoders, including incremental, absolute, linear, rotary, and more. We use state-of-the-art equipment and techniques to diagnose any issues with your encoders accurately. From there, we can provide efficient repairs or replacement services to get your equipment back up and running smoothly.

In addition to our repair services, we also offer preventative maintenance plans for encoders. These plans include regular check-ups and cleaning.

If you are an electronics repair company that is experienced in repairing encoders for your industrial equipment, look no further. Servo Spindle Specialist is standing by to assist you with the professional repair and/or maintenance of your industrial equipments encoder component.

Our receiving department carefully photographs and documents the item upon arrival.

Our receiving department carefully photographs and documents the item upon arrival. This process includes, but is not limited to:

This process includes, but is not limited to: We then prepares a detailed quote that identifies the cause of the failure and provides a comprehensive list of parts required for the repair.

We then prepares a detailed quote that identifies the cause of the failure and provides a comprehensive list of parts required for the repair. Once the quote is approved, we promptly order any necessary parts and begin the repair process. Components requiring in-house services, such as winding or machining, are sent to their respective departments for specialized attention.

Once the quote is approved, we promptly order any necessary parts and begin the repair process. Components requiring in-house services, such as winding or machining, are sent to their respective departments for specialized attention. Once repairs are complete, the item is sent to our quality control department for final testing. Here, we meticulously review the entire repair process and operate the motor on a factory-specific drive—the same type used in your machine. This ensures that your motor performs flawlessly upon reinstallation.

Once repairs are complete, the item is sent to our quality control department for final testing. Here, we meticulously review the entire repair process and operate the motor on a factory-specific drive—the same type used in your machine. This ensures that your motor performs flawlessly upon reinstallation. A fresh coat of paint does more than just make your motor look brand new—it also shields it from contaminants, helping to extend its lifespan. Our specialized painting department applies coatings tailored to your needs.

A fresh coat of paint does more than just make your motor look brand new—it also shields it from contaminants, helping to extend its lifespan. Our specialized painting department applies coatings tailored to your needs. Once the repair and refurbishment of your motor or electrical component is completed, you will updated by email of the completion of your ticket, and the return of your item will be coordinated!

Once the repair and refurbishment of your motor or electrical component is completed, you will updated by email of the completion of your ticket, and the return of your item will be coordinated!