Industrial Controls Repair and/or Replacement

Servo Spindle Specialists repairs industrial controls on various OEM produced motors and electronic components.

Industrial Controls Repair and/or Replacement: Industrial motors often have complex control systems that allow for precise adjustments and customization. If these controls are not functioning properly, it can greatly affect the performance of your motor. Our experts have the expertise to repair or replace any faulty industrial controls to ensure optimal performance.

Robotic Control Repair: As technology continues to advance, more and more industries are utilizing robotic systems for various tasks. These robots rely on precise controls to operate effectively and efficiently. If your robotic control system is experiencing issues, our team can provide expert repair services to get it back up and running in no time.

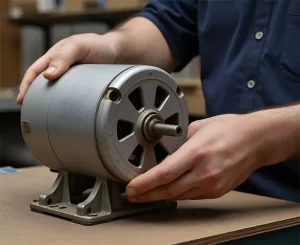

Servo Motor Repair: Servo motors are commonly used in industrial applications due to their precision and accuracy. However, like all motors, they can experience wear and tear over time. Our skilled technicians are trained to diagnose and repair any issues with servo motors, ensuring they continue to perform at their highest level.

Spindle Repair: Spindles play a crucial role in many industrial processes, such as milling, drilling, and cutting. If your spindle is malfunctioning or damaged, it can cause significant delays and disruptions in production. Our team has the expertise to repair any type of spindle and ensure it operates smoothly for maximum efficiency.

We understand the importance of minimal downtime in industrial settings, which is why we strive to complete all repairs in a timely manner without compromising on quality. We also offer expedited services for urgent repair needs.

At Servospindle.com, we pride ourselves on our exceptional customer service and commitment to providing reliable and long-lasting.

Our receiving department carefully photographs and documents the item upon arrival.

Our receiving department carefully photographs and documents the item upon arrival. This process includes, but is not limited to:

This process includes, but is not limited to: We then prepares a detailed quote that identifies the cause of the failure and provides a comprehensive list of parts required for the repair.

We then prepares a detailed quote that identifies the cause of the failure and provides a comprehensive list of parts required for the repair. Once the quote is approved, we promptly order any necessary parts and begin the repair process. Components requiring in-house services, such as winding or machining, are sent to their respective departments for specialized attention.

Once the quote is approved, we promptly order any necessary parts and begin the repair process. Components requiring in-house services, such as winding or machining, are sent to their respective departments for specialized attention. Once repairs are complete, the item is sent to our quality control department for final testing. Here, we meticulously review the entire repair process and operate the motor on a factory-specific drive—the same type used in your machine. This ensures that your motor performs flawlessly upon reinstallation.

Once repairs are complete, the item is sent to our quality control department for final testing. Here, we meticulously review the entire repair process and operate the motor on a factory-specific drive—the same type used in your machine. This ensures that your motor performs flawlessly upon reinstallation. A fresh coat of paint does more than just make your motor look brand new—it also shields it from contaminants, helping to extend its lifespan. Our specialized painting department applies coatings tailored to your needs.

A fresh coat of paint does more than just make your motor look brand new—it also shields it from contaminants, helping to extend its lifespan. Our specialized painting department applies coatings tailored to your needs. Once the repair and refurbishment of your motor or electrical component is completed, you will updated by email of the completion of your ticket, and the return of your item will be coordinated!

Once the repair and refurbishment of your motor or electrical component is completed, you will updated by email of the completion of your ticket, and the return of your item will be coordinated!