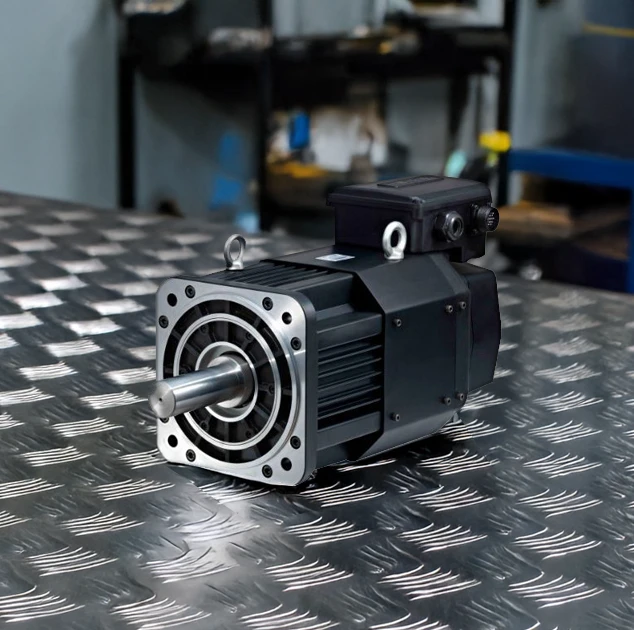

AC/DC Motor Repair Specialist

Servo Spindle Specialists repairs AC and DC motors produced by all major OEM brands. With over 20 years of experience in the industry, our team is highly skilled and knowledgeable in all aspects of motor repair.

We offer quick and efficient repairs to minimize any downtime for your business. Our technicians are trained to diagnose and fix any issues with your motor, whether it be mechanical or electrical.

Our repair services included but are not limited to:

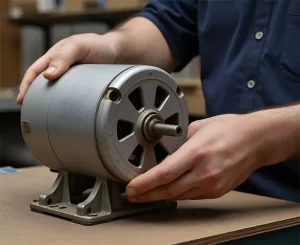

Disassemble / Reassemble: One of the key components of our repair services is disassembling and reassembling the motor. This process allows us to thoroughly inspect each individual part and identify any potential issues that may need repairing or replacing. Our technicians are meticulous during this process, ensuring every component is properly cleaned, lubricated, and aligned before reassembly.

Disassemble / Reassemble: One of the key components of our repair services is disassembling and reassembling the motor. This process allows us to thoroughly inspect each individual part and identify any potential issues that may need repairing or replacing. Our technicians are meticulous during this process, ensuring every component is properly cleaned, lubricated, and aligned before reassembly.

Bearing Replacement: Faulty bearings can significantly affect the performance and lifespan of a motor. That’s why we offer bearing replacement as part of our repair services. We use high-quality bearings from trusted suppliers to ensure your motor runs smoothly and efficiently.

Shaft Repair: The shaft is responsible for transferring torque and rotational motion. When damaged or worn out, it can lead to issues with motor performance and potentially cause damage to other components. We can repair or replace damaged shafts, ensuring smooth operation and extending the lifespan of your motor.

Spindle Repair: Horizontal or vertical machining center’s spindle cartridge repair. Our team of experts can diagnose and repair spindle issues such as bearing wear, runout, or damage from coolant contamination. We use state-of-the-art equipment and techniques to ensure your spindle is restored to its optimal performance.

Drive Repairs: The drive converts electrical energy into mechanical motion. With extensive experience in repairing and rebuilding drives, our technicians can quickly diagnose and fix any issues to get your motor running at optimal performance.

Balancing: Proper balancing of a motor is crucial for reducing vibrations and maintaining precision in operation. Our advanced balancing equipment can detect any imbalances and our technicians can correct them, ensuring smooth and precise operation.

Remagnetizing: Over time, the magnets in a motor can lose their strength, resulting in reduced performance. Our remagnetizing services can restore the magnetic field of your motor and improve its overall performance.

Waterproofing: In certain industries, such as marine or outdoor applications, motors may be exposed to water and moisture. At Servo Spindle, we offer waterproofing solutions to protect your motor from the elements and extend its lifespan.

Welding & Fabrication: Whether you need a different mounting configuration or additional components added to your motor, we have the expertise to make it happen. Our welding and fabrication services ensure your motor is repaired and/or customized to meet your specific needs.

Winding Repairs: Our skilled technicians are trained in all types of winding repairs, including rewinding coils, replacing damaged wires, and restoring connections. This is a crucial aspect of motor repair as faulty windings can cause overheating and even lead to motor failure if left un-repaired.

Winding Repairs: Our skilled technicians are trained in all types of winding repairs, including rewinding coils, replacing damaged wires, and restoring connections. This is a crucial aspect of motor repair as faulty windings can cause overheating and even lead to motor failure if left un-repaired.

Housing Repair: Motor housing damage, whether from wear and tear or accidents, can compromise the integrity of the motor. Our team is equipped to handle all types of housing repairs, including welding, brazing, and machining to restore your motor’s housing to its original condition.

Fan Replacement & Cooling System Maintenance: Overheating is a common issue that can lead to serious motor damage if left unchecked. At Servo Spindle, we can repair or replace your motors fan. We also offer cooling system maintenance services to keep your motor running at a safe temperature and prevent potential failures. We also provide guidance on best practices for cooling system usage to prolong the life of your motor.

Power Supply Repair: A faulty power supply can have a ripple effect on the performance of your motor and other components of your machinery. At Servo Spindle, we have the knowledge and expertise to diagnose and repair any issues with your power supply. We use high-quality replacement parts to ensure the longevity and reliability of our repairs.

Preventative Maintenance Services: In addition to repairs, we also offer preventative maintenance services to help keep your motors running smoothly.

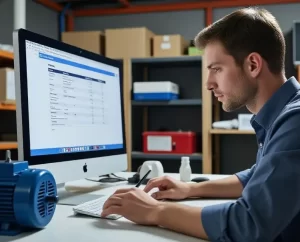

Our receiving department carefully photographs and documents the item upon arrival.

Our receiving department carefully photographs and documents the item upon arrival. This process includes, but is not limited to:

This process includes, but is not limited to: We then prepares a detailed quote that identifies the cause of the failure and provides a comprehensive list of parts required for the repair.

We then prepares a detailed quote that identifies the cause of the failure and provides a comprehensive list of parts required for the repair. Once the quote is approved, we promptly order any necessary parts and begin the repair process. Components requiring in-house services, such as winding or machining, are sent to their respective departments for specialized attention.

Once the quote is approved, we promptly order any necessary parts and begin the repair process. Components requiring in-house services, such as winding or machining, are sent to their respective departments for specialized attention. Once repairs are complete, the item is sent to our quality control department for final testing. Here, we meticulously review the entire repair process and operate the motor on a factory-specific drive—the same type used in your machine. This ensures that your motor performs flawlessly upon reinstallation.

Once repairs are complete, the item is sent to our quality control department for final testing. Here, we meticulously review the entire repair process and operate the motor on a factory-specific drive—the same type used in your machine. This ensures that your motor performs flawlessly upon reinstallation. A fresh coat of paint does more than just make your motor look brand new—it also shields it from contaminants, helping to extend its lifespan. Our specialized painting department applies coatings tailored to your needs.

A fresh coat of paint does more than just make your motor look brand new—it also shields it from contaminants, helping to extend its lifespan. Our specialized painting department applies coatings tailored to your needs. Once the repair and refurbishment of your motor or electrical component is completed, you will updated by email of the completion of your ticket, and the return of your item will be coordinated!

Once the repair and refurbishment of your motor or electrical component is completed, you will updated by email of the completion of your ticket, and the return of your item will be coordinated!